CAD/CAM? – Beginner Guide About Machining

CAD and CAM? What is that?

CAD/CAM also called computer-aided design & computer-aided manufacturing is software used to design and manufacture products and their prototype, this software usually related to CNC machines.

How does it work?

In addition to the explanation above, here is a simple explanation of how CAD/CAM works :

- Selects the right materials for the process.

- Preparing the designing and machining process from CAD and CAM.

- Inputting CAM into the CNC machine, so it can operate regarding the computed code.

- If the Machining process is done, operators can do the assembly process if needed.

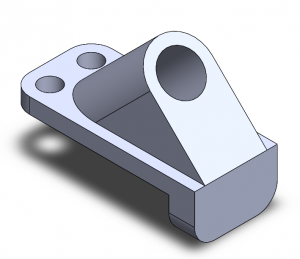

Simple Illustration how it works

CAD/CAM Advantage

To clarify these systems have some good advantage however there is disadvantages using this method, here's an explanation about that :

Advantage :

- Design flexibilities, when designing using CAD designer able to create the actual prototype.

- Faster process, in other words using CAD and CAM, has a faster time in design, manage, and test the prototype.

- Cost elimination, because there is a simulation system in CAD software it will help designers not to waste on a useless cost.

- Getting the most of CNC tools because the way it works is automated and accurate.

Disadvantage :

- It can transfer an idea to a geometrical object however it needs a good progammer.

- Processing power problem, CAD software usually consumes a lot of computer power, as a result, a high-quality computer is needed.

- Automated however maintenance and upkeep still need to be done.

Conclusion

In conclusion, we can say that CAD and CAM processes are important in the CNC design and manufacturing machining. There is a lot of type of CAD/CAM software like Autodesk, Solidworks, etc.

Have inquires that need Invesment Casting?

Gating System of Investment Casting

Our first article made investment casting seems so simple, as if you only need to make wax pattern, make mold, melt metal, and pour the metal into the mold. Unfortunately, the actual metallurgy practice is more complicated than that. This article helps understanding:...

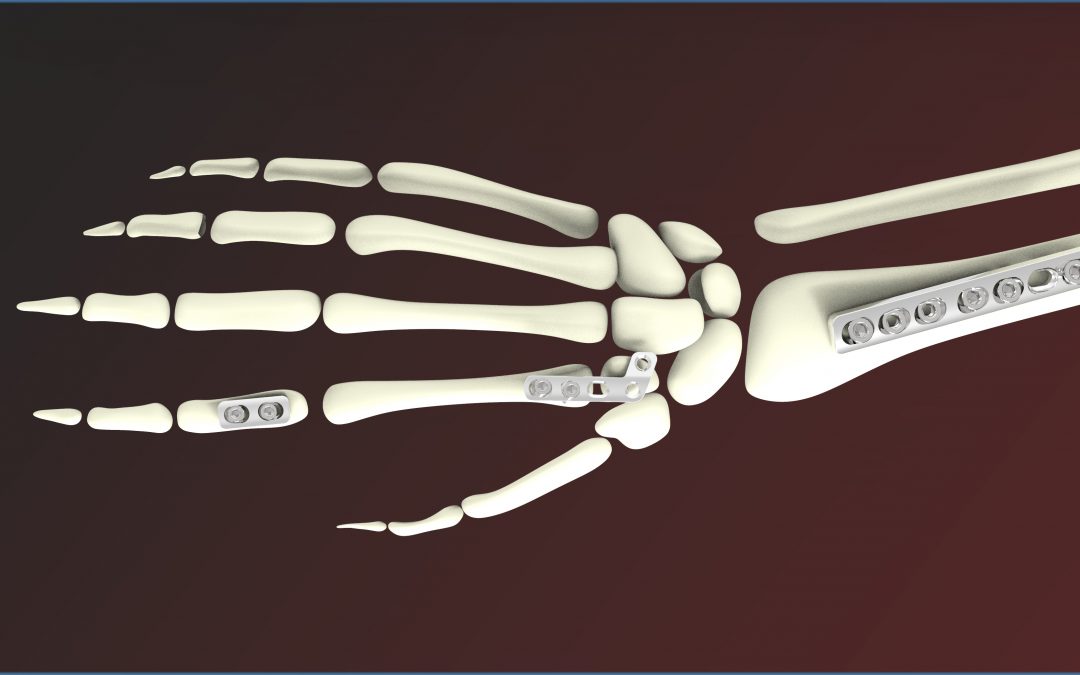

Precision Casting for Medical Industries

This article discusses why precision casting technique is interesting for the medical implant casting. As already well-known, precision casting is a reliable and versatile technique for the manufacture of precision products. These traits support the penetration of...

What is steel grade classification?

Steel Steel is the powerhouse metal for engineering applications because of its high tensile strength. In addition, steels are econominal for industrial use because of their inexpensive cost and supply stocks. The steel manufacturing technology is one of the...

What is precision casting?

What is precision casting? Precision casting (also called investment casting, lost-wax casting,and cire perdue) is a metal shaping technique to form near net-shaped products. The basic casting principle is to pour and to fill molten metal into a disposable ceramic...