Precision Casting for Medical Industries

Bone Fracture and Implants

Bone fracture occurs due to excessive force. Some major causes of bone fracture are road accidents, sports accidents, and so on. The degree of fracture also varies from a small crack to a totally shattered bone. After the bone fracture, bone misposition is pretty common. Surgeons fix the fractured bone back to the normal alignment during the surgery. They hold the bone in this position using bone fixation implants. Bone fixation implants consist of screws, nails, plates or any combination of them.

Implants are biomaterials put into the body (implanted). The purpose of implant is to support the function of broken bone during the bone regeneration period. They may or may not be removed after healing. Implants are more than just a medical device. They influence human’s life one way or another. The users of medical implants can regain their mobility and their daily life. This is why medical implant casting adds value to community.

Precision Casting for Medical Implant Casting

High dimensional accuracy and tight tolerance are crucial for medical implants. Fortunately, precision casting can satisfy these requirements. Precision casting becomes even more interesting because the shape of implants is usually complex. The shape of casting products is already near net shape in as-cast condition and only require a little more machining. Check our previous article about the details of precision casting processing.

Precision casting technique brings positive vibes to medical industry. This is especially because this technique allows mass production. This technique is also flexible to cast many shapes and sizes. Therefore, an investment casting foundry can cast a lot of different products and products variants. This is important because human body structure is unique to each person. So, more implants variations offer better options for the medical treatment.

High surface quality is necessary for implants. Even more, some implants require mirror-like quality. The surface quality of precision casting as-cast product is generally higher compared to other method. This simplifies and reduces the subsequent processes workload to produces high surface quality. Medical implant casting optimizes production time and cost.

Medical Implant Casting in Zenith Allmart Precisindo?

Zenith Allmart Precisindo focuses on providing the best precision casting service with competitive price. Instead, our sister company, Zenmed+ is the research-based determined company which will manufacture implants to fulfill the industrial needs. Pay a visit to the medical implant website!

Zenith Allmart Precisindo is more than merely your metal casting supplier or vendor. We want to grow together with you, and we will solve your manufacturing challenges using our advanced technology, professional practice, and manufacturing knowledge. Contact us for more information!

What Is Tooling In Investment Castings?

Tooling in Investment Casting is considered to be wax-injection dies that are used to create wax patterns. If you're following us from our previous trivia posts or you're familiar with how investment casting works, you already know that these wax patterns form the...

Preparing Shell for Lost Wax Casting

Description The Investment Casting Process is to coat multiple layers of refractory coatings on the surface of the wax mold. Afterward, it is dried and hardened, the wax mold is melted by heating to obtain a shell with a cavity that matches the shape of the wax...

What is ElectroPolishing?

Electropolishing or also known as electrochemical polishing, anodic polishing, and electrolytic polishing is really useful for polishing and deburring parts that have complex geometries or are fragile. Electropolishing is an electrochemical finishing process that...

What Is Cast Steel Pouring Process?

Description In investment casting, the process of pouring cast steel is a very important step. The most commonly used pouring method in investment casting is gravity pouring. First, the molten steel is poured from the furnace into the casting ladle and then...

Mold Material Defects

Mold Materials Defects In investment casting, defects are a common problem, for example, this can't be happening in the medical industry, because of its high standard so the finished product needs to be as precise as possible. Mold material defects usually caused by...

What is Casting Defects? Gas Porosity and Shrinkage

What is Casting Defects? Casting defects happen when undesired irregularity happens in the metal casting process, there is many types of defects in the metal casting industry as such: Gas porosity Shrinkage Mould material defects Pouring metal defects Metallurgical...

Mill Test Certificate EN 10204

What is Mill Test Certificate? Mill Test Certificate, is a provided by a manufacturer to certify the chemical composition and mechanical composition of the product, this thing is really important in this industry especially with products related in medical like...

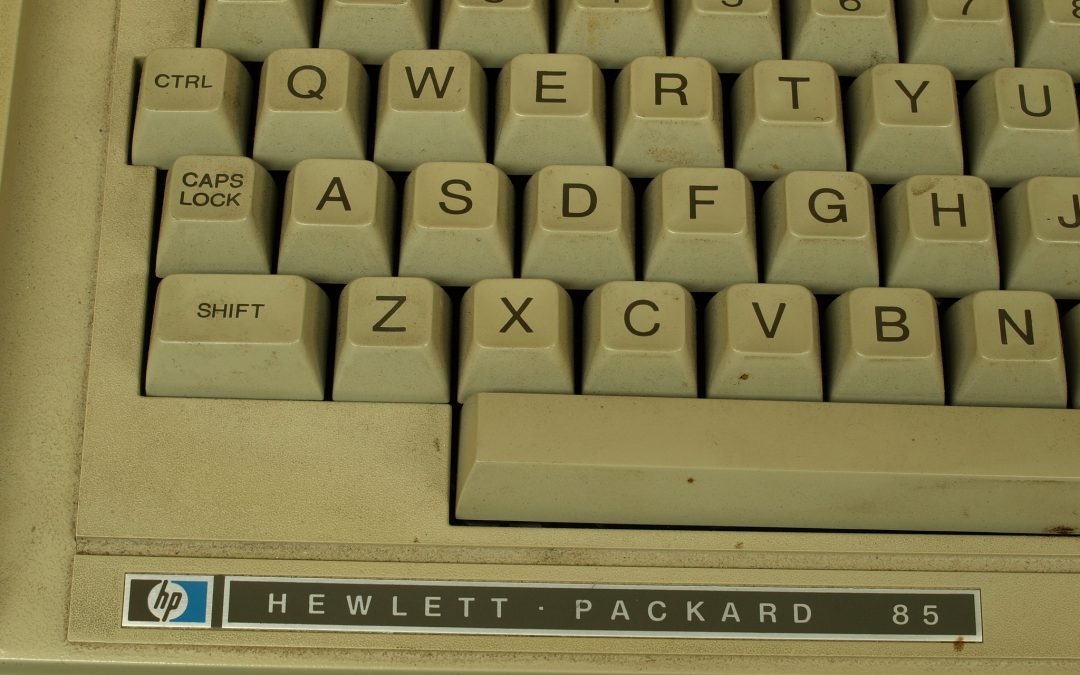

CAD/CAM? – Beginner Guide About Machining

CAD and CAM? What is that? CAD/CAM also called computer-aided design & computer-aided manufacturing is software used to design and manufacture products and their prototype, this software usually related to CNC machines. How does it work? In addition to the...

What is Drilling? A Beginner’s Guide About Machining.

What is Drilling? Drilling is a cutting process using a drill bit to create holes in the workplace, this process is the one most common method used in the machining process. Here's in CNC drilling have many scopes, starts from simple into the complex one. CNC Drilling...

What is Machining Process? A Beginner’s Guide About Machining

Machining? Machining is a process in which a controlled material removal machine is used to remove some parts from the workpiece to shape it into the intended design. This process is a part of the manufacturing of many products based on metals, however it's possible...