Mold Material Defects

Mold Materials Defects

In investment casting, defects are a common problem, for example, this can’t be happening in the medical industry, because of its high standard so the finished product needs to be as precise as possible. Mold material defects usually caused by materials, but it can happen because of other things like bad mold design, or maybe a metal that still too hot when pouring process. Here is some basic type of mold material defects :

1. Cuts and Washes

Cuts and washes are caused when the liquid metal erodes away part of the mold when pouring in and the sand doesn’t have enough heat strength to resist it. Washes and cuts show up as low bulges along a surface of the finished product, tilted toward one end where the molten metal had more force as it flowed in.

2. Drops

Drops usually look like an irregular bump that shows on the top of the products, this happens because the condition of the mold is bad so the sand drops into the liquid metal.

3. Fusion

Happen because there is some sand combined/fused with the casting.

4. Swells

This usually looks like swelling in the finished area product, usually swells in the surface area. this kind of defect happens when the mold is too soft so the weight of the liquid metal will push the sand onward.

5. Runout

Runout happens when there is a leakage in the mold, so the quantity of the liquid metal is not right.

6. Metal Penetration

Happen because mold metal penetrating the mold makes the surface looks rough.

7. Rat Tails

Rat tails happen when excessive heat of the metal causes the sand to expand.

How to Prevent Mold Materials Defects

This type of defect can be prevented by using designing a good mold and use the right temperature when pouring the metal into the mold, many solutions can be used in preventing mold materials defect, it depends on the problem that causes the defects.

Conclusion

There is a lot of defects that can happen in the investment casting process, so a discussion with an expert can help to choose the best solutions. To determine what kind of treatment for this defect, please don’t hesitate to contact us!

Have inquires that need Invesment Casting?

Gating System of Investment Casting

Our first article made investment casting seems so simple, as if you only need to make wax pattern, make mold, melt metal, and pour the metal into the mold. Unfortunately, the actual metallurgy practice is more complicated than that. This article helps understanding:...

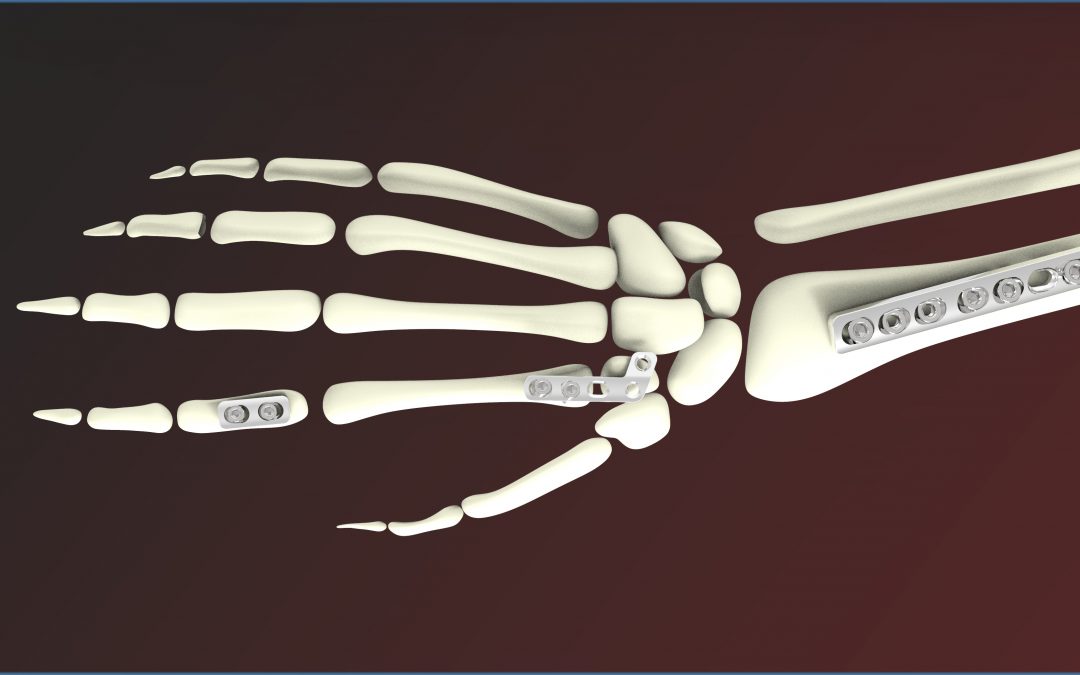

Precision Casting for Medical Industries

This article discusses why precision casting technique is interesting for the medical implant casting. As already well-known, precision casting is a reliable and versatile technique for the manufacture of precision products. These traits support the penetration of...

What is steel grade classification?

Steel Steel is the powerhouse metal for engineering applications because of its high tensile strength. In addition, steels are econominal for industrial use because of their inexpensive cost and supply stocks. The steel manufacturing technology is one of the...

What is precision casting?

What is precision casting? Precision casting (also called investment casting, lost-wax casting,and cire perdue) is a metal shaping technique to form near net-shaped products. The basic casting principle is to pour and to fill molten metal into a disposable ceramic...