Gating System of Investment Casting

Our first article made investment casting seems so simple, as if you only need to make wax pattern, make mold, melt metal, and pour the metal into the mold. Unfortunately, the actual metallurgy practice is more complicated than that. This article helps understanding: How to design gating system for precision casting?

First, let’s discuss about investment casting mold. The functions of the mold are the delivery of metal liquid and the shaping of final product. The mold is only used once and is disposable after the casting. Look into our previous article to refresh about precision casting process, especially mold production which result in negative cavity for metal filling. As already mentioned in the previous article, the cavity forms after the lost-wax process. Before filling the cavity, liquid metal passes through gating system to optimize metal delivery and improve the product casting quality.

Gating System

Liquid metal adapts to the shape of mold cavity. This is the reason metal casting has been popularly used. Product shaping is possible regardless of shape complexity as long as liquid metal can properly fill the mold. Nonetheless,the design of the mold requires more than the shape of the product.

Proper mold design makes cutbacks in problems associated with investment casting. During the mold design, you need to draw more than just the products, but also their gating system (metal delivery system) to result in high quality products. Gating system guides and delivers the liquid metal flow from the mold entrance (pouring cup) to the product cavity. The purpose of gating system is to achieve better product quality by reducing casting defects, for example: shrinkage, incomplete filling, etc.

Picture 1 Gating System Design consist of Pouring Cup+Wax Trunk, Cup Crown, and Sticks. They will later be assembled to form pattern gating system.

Gating System Design

Gating system design ensures proper metal delivery and controls the delivery rate. As such, gating system design governs the fluid flow and consequently prevents insufficient metal feeding, turbulence, and premature solidification. In this article, we will discuss components in gating system: pouring cup, feeder, runner, and ingates.

The heat transfer rate of liquid metal controls the solidification time and cooling rate. Gating system design can adjust the volume-to-surface ratio to engineer solidification time and cooling rate. If the volume-to-surface ratio increases, there are less surface area for heat transfer, and heat conducts slower. So, this adds more solidification time and vice versa. It is worth noting that the metal solidification rate may not be uniform all over the mold.

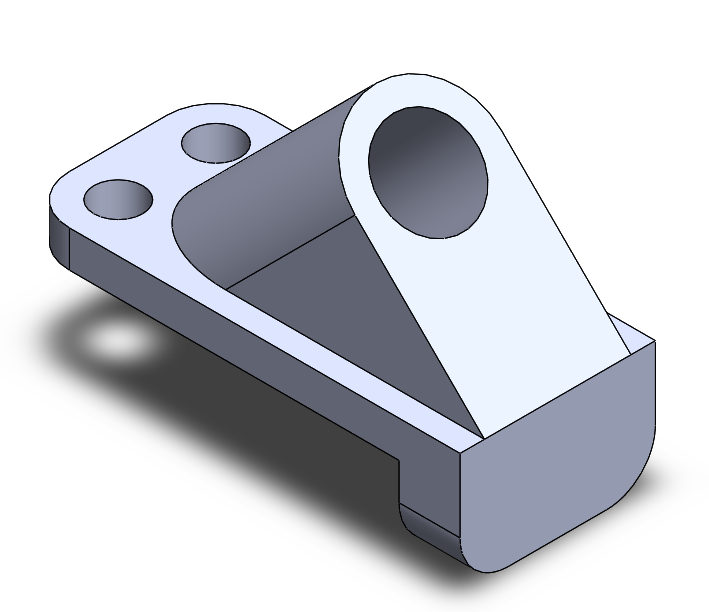

In industrial practice, gating systems are assembled from wax pattern cup, wax pattern trunk, and so on. Both product pattern and gating system pattern use the same wax material. Both of them vaporize during lost-wax process (de-waxing). Take a look at Picture 2 to compare between a product (left) and products assembled in gating system (middle, right).

Picture 2 (Left) A product example, (Middle) Top view of products assembled onto wax pattern tree, (Right) Bottom view of products assembled onto wax pattern tree.

Picture 3 Pouring Cup, Feeder, and Feeder extension.

Pouring cup design

Pouring cup (observed in Picture 3) collects pouring liquid metal and facilitates metal flow into the mold. It is the liquid metal entrance into mold cavity. In investment casting, it also acts as reservoir to supply extra metal if required.

Proper gating system design can also trap slags, dross, and inclusions from entering the product cavity. Light inclusions float to pouring cup given enough time due to lower density compared to liquid metal. They may present in the melt or/and form during pouring. Re-oxidation is the most frequent origin of inclusions. Some inclusions can also originate from the melting and casting equipment, even from the mold debris.

Feeder design

Feeder (observed in Picture 3) in investment casting serves the function of sand casting’s sprue and riser. In investment casting, wax trunk forms this feeder path. Casting design usually spares extra metal-feed volume to anticipate shrinkage during cooling (reservoir metal). During solidification and cooling, metal contracts as temperature decrease, then the reservoir metal from feeder can squeeze into the shrinkage area.This extra metal cools later, so it can fill the section where metal shrink. Depending on the shape complexity, engineers may also add extra feeders.

The presence of feeder also improves the quality of casting. Sufficient length allows metal and inclusions to separate themselves based on density, so the lighter inclusions floats without entering the casting cavity. Engineers usually locate feeders in complicated part of the product, for example close to the corner of the product. Another benefit of a feeder is to also provide spaces to trap shrinkage voids, gasses and dross. Engineers should design carefully so when feeder acts as metal reservoir, it comes from cleaner part of the feeder.

The height of the feeder is related to the velocity of the flow, which will determine the metal feeding rate. If the flow is too fast, the fluid flow can cause turbulence that can consequently cause gas entrapment. In some metals, gases form bubbles or/and stimulates oxide formation inside the mold.

During the practice of liquid metal pouring, the first metal liquid that enters the gating system and mold are more susceptible to oxidation (in the air) and inclusions (from molds, etc). As such, engineers can set feeder extension to trap these relatively dirty metal liquid. This feeder extension can also be seen from Picture 3.

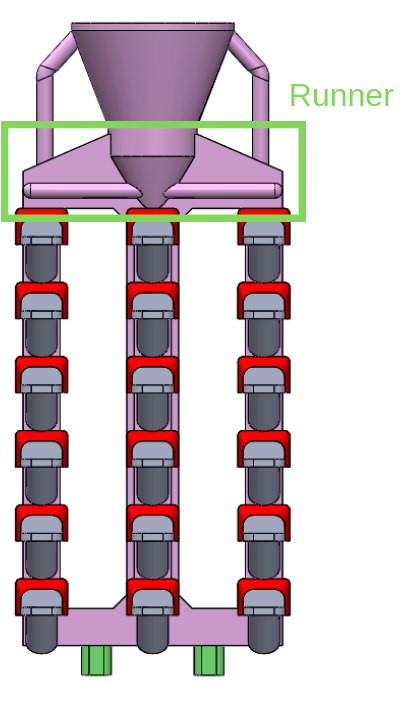

Picture 4 Runner

Runner design

Runner (observed in Picture 4) distributes liquid metal to optimize metal supply mechanism. It guides liquid flow to fill targeted product cavity. Also, it allows multiple metal delivery channel, which enables a mold to hold multiple product cavities. This adds economical value to foundry practice. Adding more parallel runners can also help facilitating better metal filling in complex or heavy parts. Size of the runner also influences feeding rate into ingates, which later relates to the feeding rate into product cavity.

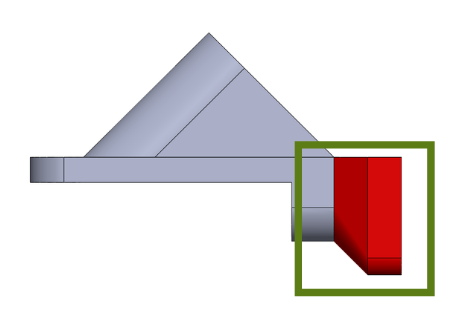

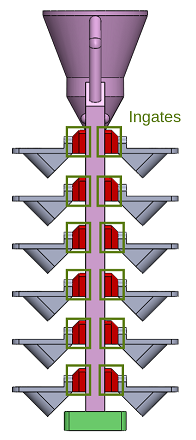

Ingates design

Ingate (observed in Picture 5) is the last gating system component right before the casting product, connecting runners and products. Engineers usually connect ingates onto the thicker part of the metal to prevent metal solidify early and block the pathway. In some of these cases, engineers use mutiple ingates onto the same product to anticipate if any of the ingates become hot spot. Please note that adding more parallel ingates slows feeding rate into the product cavity. To tackle this issue, engineers can reduce the size of ingates, thus increasing feeding rate.

Picture 5 (Left) Ingate connects to the product (Right) Ingates connect products and gating system.

Efficient Gating System Design

The economical aspect is as important as the engineering aspect, so gating system design needs to be cost efficient. The most straightforward indicator is the yield ratio, which is the weight ratio of the product in comparison to the total cast (product+gating system). Good gating system design performs at high yield ratio without compromising the gating system function. Foundry practice returns and recyles the leftover gating system to supply the following casting batch.

In addition, engineers also consider the subsequent processing stages, such as cutting, blasting, as so on. Practically, it should be easy to remove gating system and product. Otherwise, the cutting stage will be costly. Experienced engineers estimate gating system design cost as the final product production cost, not just product casting cost.

Gating system design in Zenith Allmart Precisindo?

Zenith Allmart Precisindo employs a team of experts with 20 years of experience in precision casting/lost-wax casting industry. We have cast a wide variety of products, from a small medical implant to a large impeller and we can definitely design the gating system of your products. Please check our portfolio here to learn more about our company products!

Zenith Allmart Precisindo is more than merely your metal casting supplier or vendor. We want to grow together with you, and we will solve your manufacturing challenges using our advanced technology, professional practice, and manufacturing knowledge. Contact us here for more information!

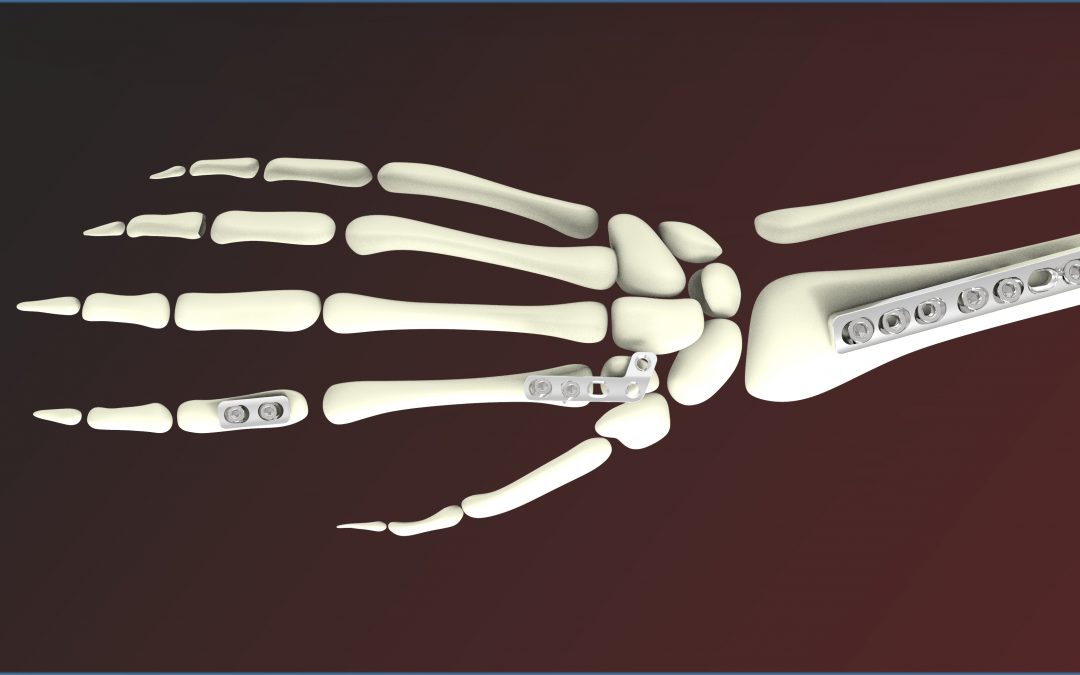

Precision Casting for Medical Industries

This article discusses why precision casting technique is interesting for the medical implant casting. As already well-known, precision casting is a reliable and versatile technique for the manufacture of precision products. These traits support the penetration of...

What is steel grade classification?

Steel Steel is the powerhouse metal for engineering applications because of its high tensile strength. In addition, steels are econominal for industrial use because of their inexpensive cost and supply stocks. The steel manufacturing technology is one of the...

What is precision casting?

What is precision casting? Precision casting (also called investment casting, lost-wax casting,and cire perdue) is a metal shaping technique to form near net-shaped products. The basic casting principle is to pour and to fill molten metal into a disposable ceramic...